![]()

|

Vacuum Pump Assembly Instructions: "Warning: Applying a vacuum, even a moderate one, to a vessel not designed to be pressure-resistant carries an inherent danger. Malleable vessels (thin steel or plastic) may deform or collapse. Rigid but brittle vessels (i.e. glass) need internal support, or they may catastrophically implode. Never apply a vacuum to an empty carboy. If there is any doubt about the strength or integrity of a vessel, do not apply a pressure differential to it. In addition, you must wear proper safety equipment, including eye protection at all times when applying a vacuum to any sealed vessel." Tim Vandergrift WineMaker Mag. Feb. 2007. |

|

|

|

1 ) Oil - Your Vacuum Pump must be lubricated to prevent damage. Open Red Oil Cap and fill with "Vacuum Pump Oil" provided to level on side (see below). Never run your pump without sufficient oil. 2 ) Screw the brass relief valve onto the threaded side "T" as shown. It's a good practice to wrap the threads with Teflon plumbers tape. This valve allows you to control the vacuum and resulting fill speeds.

Note: During operation it is normal for small amounts of oil to wick thru the exhaust vent. It is also normal for the unit to generate a small amount of smoke at full vacuum under a heavy load. |

|

|

|

|

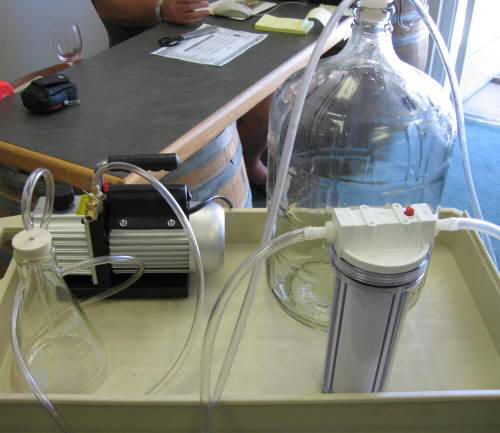

Warning: Always use an overflow protection container with your vacuum pump. Fluid in your pump will void the warranty! 5) Connect your vacuum overflow assembly as shown.

|

|

Racking: 6) To Rack from Carboy to Carboy:

|

|

|

Filtering:

7) To filter simply place a filter cartridge inline between your carboy and vessel. The wine is pulled thru the filter in a traditional manor. |

|

|

Barrels - Filling or Topping Barrels:

The bung makes a tight seal. A vacuum is pulled, evacuates the barrel and pulls wine in thru the tube on the left. The barrel is full when wine starts being visible in the vacuum line (collected by the overflow assembly). No mess.

|

|

©2002-2007 The ValleyVintner. All Rights Reserved |

![]()